With the rapid growth of the new energy industry and the increasing demand for lithium batteries, installing fire alarm systems in lithium battery workshops has become a crucial safety measure. As the world transitions to a “carbon-neutral” era, electric vehicles (EVs) have emerged as a leading direction in the global automotive industry.

China has witnessed an unprecedented rise in the popularity of EVs due to strong government support and policies promoting the development of new energy vehicles. This surge in the EV industry has fueled the rapid expansion of the lithium battery market, necessitating a focus on ensuring safety in battery production facilities.

Why Install Fire Alarm Systems in Lithium Battery Workshops?

Lithium battery electrolytes can rapidly decompose and release heat when exposed to a large amount of water, potentially leading to explosions. Lithium battery production workshops often contain flammable or toxic gases, such as ammonia, chlorine, hydrogen fluoride, hydrogen sulfide, carbon monoxide, hydrochloric acid, fluorine compounds, and phosphoric acid. These gases above safe limits pose significant fire and poisoning hazards.

During environmental testing processes, battery damage can result in leaks of carbon monoxide (CO), hydrogen (H2), and hydrogen sulfide (H2S). Therefore, it is advisable to install hydrogen and carbon monoxide sensors in lithium battery production workshops to detect low-concentration gas leaks intelligently. Once the predefined threshold is reached, these sensors can trigger alarms, enabling prompt evacuation of personnel, ensuring their safety.

Recommended Fire Alarm System Components:

Hydrogen Sensor: TGS2615-E00

The TGS2615-E00 hydrogen sensor effectively detects hydrogen leaks in lithium battery workshops. It features an enhanced selective filter layer, low power consumption, long lifespan, low cost, and a simple application circuit. This sensor offers excellent reliability and cost-effectiveness, making it an ideal tool for hydrogen leak detection in lithium batteries.

Carbon Monoxide Sensor: TGS5141

The TGS5141 carbon monoxide sensor from FIGARO, Japan, is highly sensitive, reliable, and long-lasting. It is particularly suitable for detecting fires in lithium batteries. Carbon monoxide is typically generated in large quantities before lithium batteries catch fire, making monitoring its concentration an effective solution.

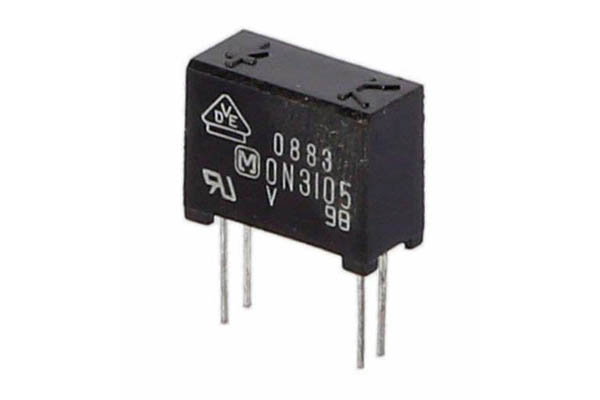

Methane/Carbon Monoxide Sensor: TGS3870

The TGS3870 methane/carbon monoxide sensor is a microbead-type semiconductor gas sensor used to detect methane and carbon monoxide. This sensor employs a microbead gas sensing structure. It utilizes periodic variations in high and low voltages applied to the sensor’s heater, enabling it to detect both methane and carbon monoxide. The gas sensing element is extremely small, and the heater consumes only 38mW (average).

Conclusion:

As the demand for lithium batteries grows in the new energy industry, ensuring safety in battery production facilities is paramount. Installing fire alarm systems, including hydrogen, carbon monoxide, and methane/carbon monoxide sensors, provides an effective safety precaution against potential hazards.

These alarm systems play a vital role in detecting gas leaks, triggering timely warnings, and facilitating the swift evacuation of personnel in case of emergencies. By implementing robust fire alarm systems, lithium battery workshops can prioritize the safety of their workers and contribute to the sustainable development of the electric vehicle industry.